What Is The Reason For The Relaxation Of The Film in The Blowing Machine

Film relaxation is a common quality defect in film blowing production, which can lead to wrinkles, loose rolls, and uneven tension in finished films—directly affecting subsequent processes like printing, bag making, and packaging. To resolve this issue, it is essential to identify its root causes. Below is a detailed breakdown of the seven key factors behind film relaxation, with expanded analysis of their mechanisms and practical impacts.

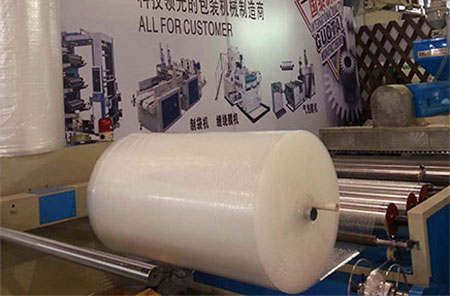

Blown Film Machine working properly

Uneven Thickness of the Film

Uneven film thickness (along the length or width) is a primary driver of local tension imbalance during winding, ultimately causing relaxation. When a film has thicker and thinner regions, the thicker sections require greater tension to stay flat during winding (due to higher material density and resistance), while the thinner sections are more prone to overstretching or insufficient tension. This mismatch means thinner areas may “relax” from lack of pulling force, while thicker areas may accumulate and wrinkle from excessive resistance.

This unevenness is closely tied to three production factors:

-

Extruder performance: Fluctuations in the extruder’s barrel temperature (e.g., a 5–10°C drop in one heating zone) cause incomplete or uneven melting of raw materials. For example, if the barrel’s middle zone is underheated, the plastic there remains partially solid, reducing extrusion flow and creating thinner film spots.

-

Screw configuration: Improper screw design (e.g., mismatched pitch or compression ratio) disrupts uniform material conveying. A screw with inconsistent pitch may cause molten plastic to “pile up” in some sections, leading to sudden spikes in extrusion volume and thicker film areas.

-

Raw material distribution: Uneven raw material particle size (e.g., mixed fine and coarse granules) or uneven additive mixing (e.g., uneven plasticizer dispersion) reduces material fluidity. This makes the molten plastic exit the die unevenly, resulting in thickness variations across the film.

Improper Cooling of the Bubble Cooling Air Ring

The cooling air ring is critical for rapidly solidifying the thermoplastic bubble (formed after plastic is extruded from the die) in film blowing. Its cooling effect directly determines the uniformity of the film’s physical properties. If the air ring’s cooling is uneven, some parts of the bubble cool too quickly, while others cool too slowly—creating differences in the film’s crystallinity, hardness, and ductility.

For instance:

-

If the air ring’s nozzles are blocked by plastic residues (from volatile substances in raw materials), the blocked area delivers less cool air. The corresponding bubble section cools slowly, remaining semi-molten with high ductility. During traction, this section stretches more than fully cooled areas, leading to thinness and relaxation when wound.

-

If the air ring’s angle is misadjusted (e.g., tilted to one side), cooling air focuses on one part of the bubble. The overcooled section becomes brittle and less stretchable, disrupting tension balance and causing relaxation in adjacent flexible areas.

3. Local Cooling of the Membrane Bubble Before Entering the Clamp

The clamp (nip rolls) flattens the tubular bubble into a flat film and provides stable traction. If the bubble cools locally before touching the clamp, the material in that area solidifies prematurely—losing flexibility and ductility. This creates a mismatch in mechanical properties between the locally cooled section and the rest of the bubble.

Common causes of local cooling include:

-

Workshop airflow (e.g., direct air from air conditioners or fans blowing onto the bubble), causing sudden temperature drops in specific spots (e.g., a 20–30°C drop in 1–2 seconds).

-

Contact with cold equipment (e.g., unheated guide rolls near the clamp), which saps heat from the bubble’s surface.

When the prematurely solidified bubble enters the clamp, the rigid section cannot stretch with the rest of the film. The flexible areas stretch normally, while the rigid section resists—leading to tension imbalance and relaxation in the stretched areas during winding.

4. Inconsistency Between the Mold Mouth and the Center of the Traction Roller

The mold mouth (die head) is the “exit” for molten plastic to form the bubble, and the traction roller provides upward pulling force. For stable tension, the mold mouth’s centerline must align with the traction roller’s centerline. Misalignment forces the film to be pulled at an angle, causing uneven tension across its width.

For example:

-

If the mold mouth is offset 3–5mm to the left of the traction roller’s center, the left side of the film faces a longer traction distance and higher tension, while the right side has shorter distance and lower tension. Over time, the right side (with insufficient tension) accumulates during winding, showing obvious relaxation.

-

Misalignment often stems from poor equipment installation (e.g., uncalibrated die head position) or long-term wear (e.g., bent traction roller brackets from heavy use).

5. Inconsistent Cutting Edge and Angle When Cutting the Edge with the Cutting Blade

Edge cutting trims the film to the required width, and precision here is key to maintaining winding flatness. If the blade’s edge is unevenly worn or its angle is improperly set, the cut edge becomes rough or irregular—disrupting overall tension balance.

-

Uneven blade wear: A dulled or nicked blade edge tears the film instead of cutting it cleanly, creating burrs. These burrs increase friction between the film and winding roller, reducing local tension and causing relaxation.

-

Incorrect blade angle: A too-steep angle (e.g., 60° instead of the standard 30–45°) makes the blade slip on the film, leaving uneven edges. A too-shallow angle (e.g., <30°) presses too hard on the film, stretching the edge and creating thin, tension-weak areas that relax during winding.

6. Inconsistent Pressure on the Pressure Roller During Winding

The winding pressure roller applies uniform pressure to the film, ensuring tight, flat rolls. If pressure is uneven (across the roller’s length) or the roller malfunctions, the film’s winding density varies—leading to relaxation.

- Uneven pressure: For example, if the left end of the pressure roller has 0.3MPa pressure while the right end has only 0.1MPa, the left side of the film is pressed tightly (small roll diameter), while the right side is loose (large roll diameter)—appearing as relaxation on the right.

- Malfunctions: Leaking pneumatic cylinders (reducing pressure on one end) or worn bearings (causing uneven pressure distribution) are common culprits. A stuck pressure valve can also cause sudden pressure drops in specific areas, leading to local relaxation.

7. Uneven Seam of the Stabilizing Plate

The stabilizing plate keeps the flat film stable before winding, preventing lateral movement. Its seams (e.g., between Splicing sections) must be smooth—uneven seams create uneven force on the film as it passes through.

-

If a seam is raised by 0.2–0.3mm (from poor installation or deformation), the film faces greater resistance at the raised spot, slowing its movement. The film behind the seam accumulates due to reduced speed, while the film ahead stretches normally—creating tension imbalance and relaxation in the accumulated area.

-

Stabilizing plate seams often become uneven from long-term heat exposure (e.g., warping from proximity to the extruder) or physical impact (e.g., accidental bumps during maintenance).

For You!